Approach: your complete sea fastening project in good hands

To create your perfect superyacht, you bring together the best specialists: experts who know your market and who know what is important – because every detail has to be right. Schuerman Sea Fastening has been a leading specialist in fastening and protecting tableware and glassware for more than 15 years. We deliver your complete sea fastening project, from the initial design to timely installation on board. You can rely on us.

When should you call on us?

We prefer to be part of the design process of your yacht from the beginning. This is because, thanks to our expertise and experience, we can help determine the best design for the available space, and also give advice about where the storage space should be located. This can save a lot of time later.

But what if you call on us during the final phase? That's no problem either. During this hectic stage, we would be happy to unburden you by supplying a complete made-to-measure sea fastening solution for all your glassware and tableware. We guarantee the highest quality and timely installation on board

Proven project approach

Many leading yacht builders and designers in Europe appreciate our approach, and are happy to work with us. This is due to our expertise, passion, flexibility and clear communication. Together, we rapidly arrive at the desired result, based on the following four stages:

1. Inventory and measurement

Every project begins with making an inventory, preferably on location. All involved parties are present (the yacht and/or interior builder and the yacht owner or his representative). Together, we examine which tableware and glassware has been selected and give advice about where it should be stored. All items are 3D scanned.

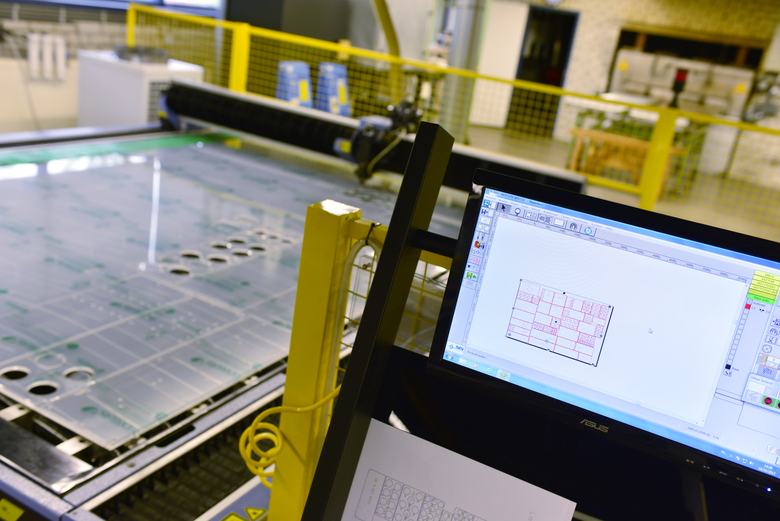

2. Design and engineering

Using our 3D CAD/CAM system, we start working with the information gathered. We prepare a design with an optimal layout, so that the tableware and glassware is safely secured in the available space. We also take other practical and aesthetic requirements into account. Following this, we prepare overview drawings with isometric views, which we present for approval. We do not prepare the production drawings until you are completely satisfied.

3. Production

The production of sea fastening solutions is precision work. The plastic sheets are cut to size using innovative laser technologies. They are then subjected to heat treatment (tempering) to remove the stresses that arise in the material. This increases its lifespan. Finally, the plastic sheets are bonded using special adhesives that are almost invisible. Polishing is unnecessary: laser cutting produces smooth edges, and thus an ultra-high-quality finish.

4. Installation

Once the custom-made sea fastening products have been subjected to a strict final inspection, we take care of the installation on board. With great precision, we not only check whether they fit inside the cupboards but also that the tableware fits. Of course, we work very carefully and discretely, and ensure that nothing is damaged and that no waste is left behind. This means you can immediately enjoy your new interior.

Get in contact with us

Would you like more information about our approach or to discuss the possibilities for your project? Don't hesitate to contact us for an appointment.